Wageningen University

24/7 Optimisation

Wageningen University & Research (WUR) is the world's most sustainable university according to UI Green Metric World University Ranking van de Universitas Indonesia. In sustainability benchmark SustainaBul by the Cooperative 'Learning for Tomorrow', the WUR ranked first in terms of sustainability no less than six times. Sustainability is ingrained in the DNA and mission of the WUR; ('To explore the potential of nature, to improve the quality of life'). Not surprisingly, therefore, WUR is working hard to become fully CO2 neutral.

One of the measures along the way is to look at how adaptive and predictive climate controls can be used to save as much energy as possible, without compromising on comfort. In doing so, it is important that a possible solution can be applied in several WUR buildings at the same time.

To investigate this, WUR, together with Priva Partner VB Optimum and others, has started a 'health check' (pilot) of the climate systems.

Preconditions for the pilot are that the comfort level for users remains at least the same during the pilot and that insights are gathered to get the university off the gas as soon as possible. Also, as much energy as possible must be saved for a total area of over 10,431 m2.

In particular, consolidating the comfort level in campus buildings provides many starting points for saving energy, according to Measuring and Control Engineering Coordinator Wim Bruins.

Bruins says: "The building users are on our campus for a large part of the day, so the indoor climate has to be optimal. An optimal indoor climate means, among other things, ensuring a constant, pleasant temperature in all seasons and sufficient ventilation.'

'By further automating our climate system, by making it proactive and predictive, the system controls the indoor climate almost completely autonomously. That's the idea. That way, we can achieve both a pleasant indoor climate and also nice energy savings.'

'Together with Frank Visscher of VB Optimum, technical service BIS, Eric Steinbach, (section head of construction and housing management), Hans van der Lienden, (technical building manager) and Henk van Huenen, (GBS manager of Bouw en installatieservice), we started this pilot. We also closely involved our site manager in the project.'

Why did you choose Priva ecoBuilding?

'We already knew Priva because they supplied the building management system through Priva partners. So a large part of our buildings are already running on Priva and we have been using it as a standard for years. We also use ErbisOne as an energy registration system'.

'VB Optimum picked up the entire ecoBuilding pilot project for us from the start of implementation to realisation of what it is today. This included guidance and monitoring of the system. For this, they engaged Rensen Building Environments who, in collaboration with VB Optimum, carried out the project.'

ecoBuilding: fully automatic energy control

'In collaboration with Rensen Building Environments, VB Optimum installed ecoBuilding for us on top of our existing climate system. ecoBuilding is a layer of Cloud-based software that uses a digital twin and AI to calculate exactly how much energy is needed to get the zones in our building to the right comfort level. We want to see if we might deploy ecoBuilding at multiple locations if the good results we are experiencing so far continue.

What about the first results

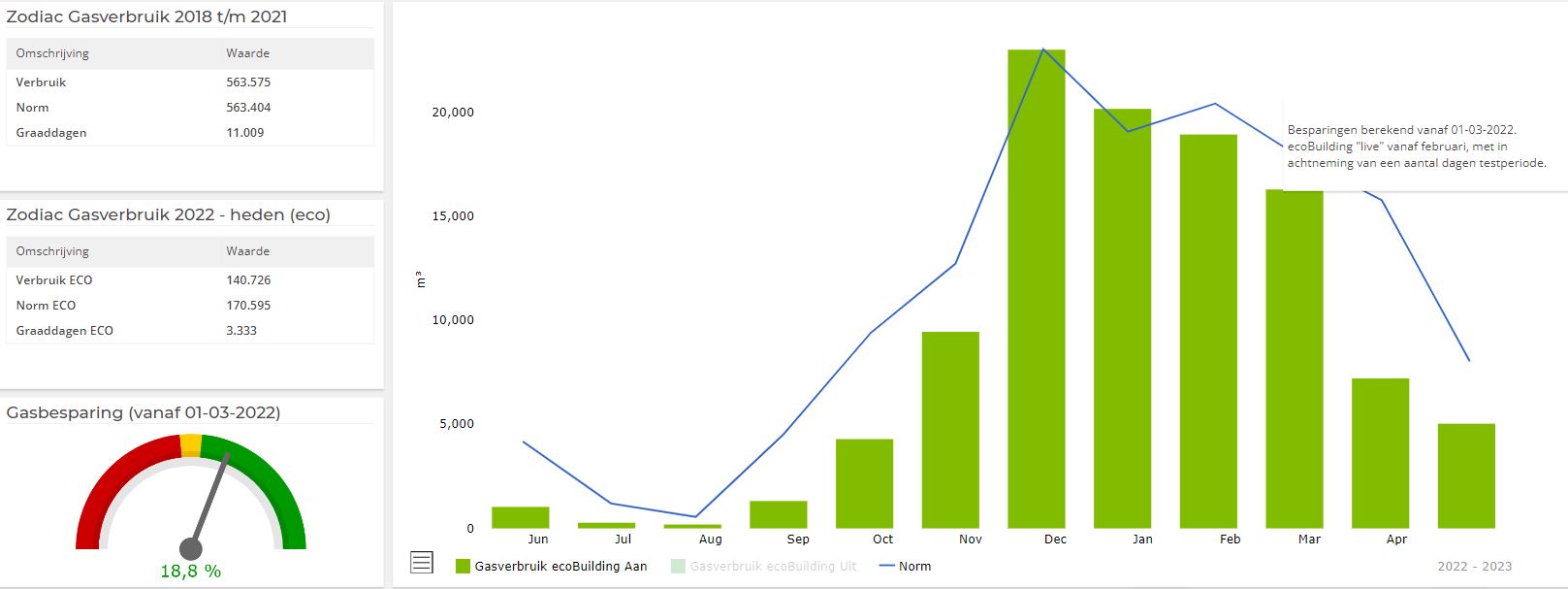

'We have now been using ecoBuilding since March 2022 and are seeing nice energy savings compared to how our system was performing before. Of course, we want to see if this trend continues over a longer period, to draw conclusions. However, the initial results are good. What is also nice: this energy saving means we don't need to lower the indoor temperature any further and comfort is maintained.

What needs to be improved? What does the future look like?

'In the coming months, we will be closely watching how ecoBuilding automatically optimises our system, how much energy we save, and whether comfort targets are met. Also, most of the buildings on our campus will get a different power plant and a connection to the collective CHP system. With this, we are increasingly moving away from gas. For now, I am happy with the energy we are already saving and that students and colleagues can study and work in a nice indoor climate.'